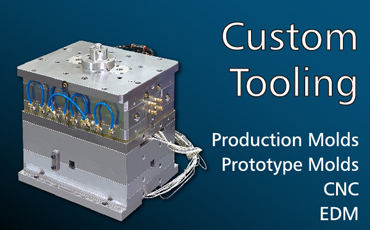

CUSTOM TOOLING

When you choose Shenyuann for your tooling needs, we have the experiences and capabilities to make design concepts to efficient production of finished product within reduced lead time at competitive prices. During the tooling development stage, customers work with the same tooling engineer team, from DFM review to parts production so no loss of knowedge gained for any future reviews by cutomer requests. Upon receiving the 3D CAD, our Sales team work closely with our Engineering team to develop instant quotation and provide technical feedback for customer review. Our tooling design team uses softwares such as Pro-E, AutoCAD, and Moldex 3D, to provide mold flow analysis and DFM in English. Shenyuann pays attention to details for mold development to meet customer demands for excellent surface texture treatment and provides feasible options to solve tooling issues without implementing major ID change. With our CAD software, CNC machine, EDM/Mirror EDM equipment, and highly experienced tooling craftsmen, the quality of molded parts will exceed your expectations. Shenyuann has the best interests to make high quality molds, so that our in-house plastic injection will be efficient and reliable for mass production. We specialize in making molds for single injection, double injection, insert molding, three-plated, indexing plate, etc. Our engineering team is familiar with various different resin types provided by many suppliers, such as SABIC, EMS, LEXAN, KRAIBURG, EVONIK, HUNTSMAN, DOW CORNING, and takes each resin characteristics into account for tool design. Over the years, Shenyuann's capabilities have grown from making tools of simple designs to more complex designs of new electronic consumer products, such as GPS navigation, outdoor wearables, waterproof function electronic devices.