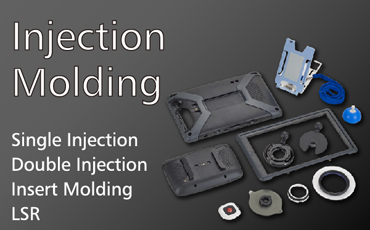

INJECTION MOULDING

Shenyuann has been a leading plastic injection molder for over 25 years, serving customers with world-class quality products. We provide high-quality custom injection molding for plastic parts along with very low costs and assign dedicated engineers to assist customers from development to mass production. All production molds are made in our factory with the best appropriate materials and mass production efficiency is maximized by our highly experienced tool makers. Our factory utilizes a wide range of molding machinery which specializes in single injection, double injection, and insert molding. Apart from commonly seen double injection molding techniques, we specialize in in-mold assembly for parts with movable joint feature, and indexing plate for allowing alternative designs on cavity/core sides. The plastic injection machine on site can accommodate molding up to 320 tons tools, with well-trained operators working shifts 24 hours per day. Due to our experience in molding parts with a wide range of plastic resins, we can offer comparison and analysis for customer to choose the most appropriate material to meet function, quality, and cost needs. Shenyuann has been moulding sub-assembly plastic parts for consumer electronics related products, such as: GPS devices, outdoor sports cameras, outdoor wearables, Iphone covers, etc. These products require exceptional cosmetic quality, which can be done by tooling mould treatment, molding process, cosmetic finishes. Our molding expertise also allows parts to have waterproof function up to IPX8, which are 100% inspected on the assembly line. Shenyuann is always accumulating more experiences in making different types and complexity of products, such as expanded our factory resources by acquiring LSR molding equipment. We have the confidence in our expertise to provide for our customers to meet specific design, quality, performance and production needs.